VRTNÁ SOUPRAVA AMERICAN AUGERS

Záruka zdárného provedení záměru investora, či zadavatele: používáme celosvětově osvědčenou strojní technologii firmy American Augers.

.

Technické specifikace

|

|

|

|

Engine Type: Detroit Diesel, turbodiesel water cooled with electric start.

Rating: 106 HP (79 kW) @ 1400 RPM continuous duty.

Torque: 342 ft lb (463 Nm) @ 1400 RPM

Fuel Capacity: 15 U.S. Gallons (55 litres)

Clutch: Dry, spring applied 13 inch (330 mm) diameter.

Transmission: Spicer five speed constant mesh.

Ratios: 1st gear - 7.17:1 2nd gear - 4.21:1 3rd gear - 2.54:1 4th gear - 1.45:1 5th gear - 1.00:1 Reverse - 7.17:1

Gearbox Ratio: 54.2:1

Auger Drive: 4 inch hex (101.2 mm).

Working Range: 12 to 48 inch (305 to 1219 mm) casing diameter.

|

|

|

1st Gear: 116,104 ft lb (157,437 Nm), 6 RPM

2nd Gear: 68,173 ft lb (92,442 Nm), 10 RPM

3rd Gear: 41,130 ft lb (55,773 Nm), 17 RPM

4th Gear: 23,480 ft lb (31,839 Nm), 29 RPM

5th Gear: 16,193 ft lb (21,958 Nm), 42 RPM

Reverse: 116,104 ft lb (157,437 Nm), 6 RPM

*These are net figures. A deduction has already been taken in consideration of hydraulic and mechanical loss.

|

|

|

Pressure: 6,000 PSI (41,370 kPa)

Thrust (max): 900,000 lb (4,004 kN)

Pump Type: Axial piston with load sensing constant speed or pressure control.

Output: 38 GPM (144 lit/min).

Cylinders: Three 8 inch bore X 35 inch stroke (203.2 X 889 mm).

Suction Filter: Screen, 149 mesh.

Return Filter: 10 micron replaceable element.

|

|

|

Base Assembly, Split Machine: 7,900 lb (3,585 kg)

Sub-Frame Assembly, Split Machine: 6,200 lb (2,815 kg)

Casing Pusher: 1,200 lb (545 kg)

Master Track: 1,000 lb (454 kg)

Extension Track: 2,000 lb (910 kg)

|

|

|

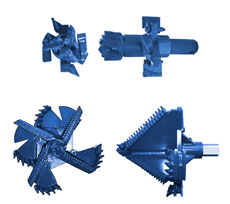

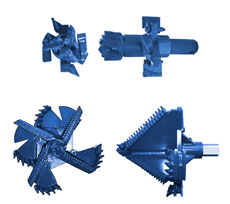

| American Augers supplies a full range of auger sections, dirt and rock cutting heads, hex adapters, casing size adapters, support equipment and repair components developed throught our 25 years' experience in the auger boring industry. |

|

|

| The model 42-48 comes with four base unit hook-roller holddown assemblies, low center line and wide stance to provide stability and to aid in the prevention of machine rollover. The spoil door is spring-loaded to deflect thrown debris. There is an emergency shutdown switch at the operator's station. Vivid graphics guide safe and proper machine operation. Instruments include: engine tachometer, engine warning lights, hydraulic thrust pressure gauge. Track brake keeps machine from creeping while idling. Quick release hook rollers easily release from track. |

|

|

| The model 42-48 has a power winch intended for rapidly pulling the boring machine back to its starting position on the track. The winch has a free-wheeling clutch to pay out wire rope. The winch can be controlled from the main hydraulic valve. The winch is not intended for pulling casing or auger sections. |

|